Automated quick-response returns solutions

Rapid, automated returns processing

Overview

Handling high volumes of returns can place a serious strain on warehouse operations, especially in fast-paced e-commerce environments. Inteq’s automated returns solutions are designed to simplify and speed up this process, reducing manual handling while improving traceability, accuracy, and overall efficiency. By combining advanced automation with our proprietary Inteq Warehousing Software (IWS), we help businesses accelerate refund cycles, reintegrate products into inventory faster, and lower the total cost of returns. This approach to returns processing helps protect your margins, enhance customer loyalty, and keep operations flowing.

Returns

Applications

- Returns management is critical in today’s high-volume, high-speed warehouse environments. Inteq’s solutions are built to support operations where efficiency, traceability, and fast turnaround are essential.

- E-commerce and retail warehouses processing high volumes of customer returns.

- Facilities requiring rapid inspection, sorting, repackaging, and restocking.

- Operations integrating returns with outbound fulfilment workflows.

- Businesses aiming to increase visibility and reduce costs across returned inventory.

- Warehouses managing a complex mix of products, packaging types, and labelling requirements.

Our solutions

Auto-bagging and auto-boxing

Inteq’s automated packaging systems help you repackage returned goods quickly and securely, cutting down on manual tasks and errors. These systems automatically select the right bag or box, apply customised configurations, and prepare products for resale or disposal with minimal downtime.

RFID technology

RFID tagging removes the need for manual barcode scanning, enabling instant tracking of returned goods throughout the warehouse. Staff can access item data on demand, improving visibility, accuracy, and processing speed from the moment goods re-enter the system.

Pouch sorters

Pouch sorters offer a fast, space-efficient way to hold returned items in the dispatch area, ready for immediate reuse. By buffering fast-moving returns near the packing line, they eliminate the need to send goods back to distant storage, reducing delay and handling time.

Autonomous Mobile Robots

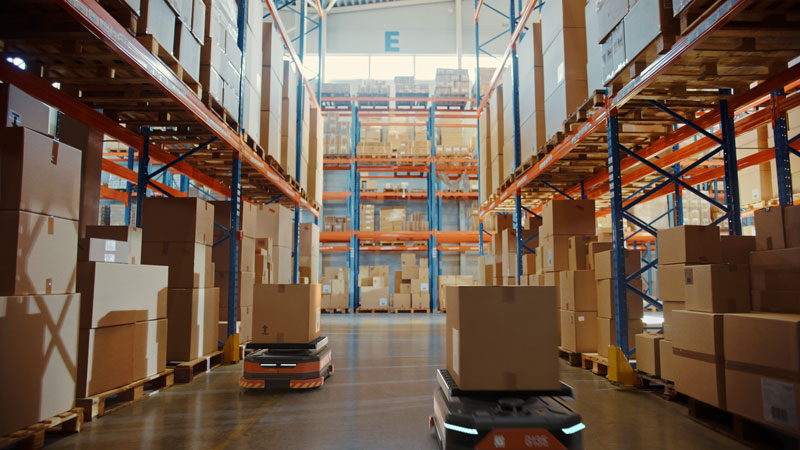

AMRs enhance flexibility by transporting returned items to and from workstations for inspection, repackaging, or restocking. These scalable, low-CapEx robots support goods-to-person workflows and free up staff to focus on value-adding tasks.

Automated Conveyor Systems

Configured for efficient reverse logistics, automated conveyors guide returned products through inspection, sorting, and packing zones without manual intervention. Fully integrated with IWS and other technologies, these systems keep your returns process fluid and bottleneck-free.

Explore our other solutions

Returns are just one of our offerings. Discover how our full range of solutions can optimise every area of your warehouse operation.

Discover our complete range of services, from initial consultation and tailored project design to hands-on implementation, training, and long-term support.

Testimonials

Read what our clients are saying about our solutions.

Discover what we can do for you today.

Returns don’t need to slow you down. Talk to us today to find out how we can help you build a returns process that’s intelligent, automated, and built to scale.

Contact us

Carl Moore

Carl Moore